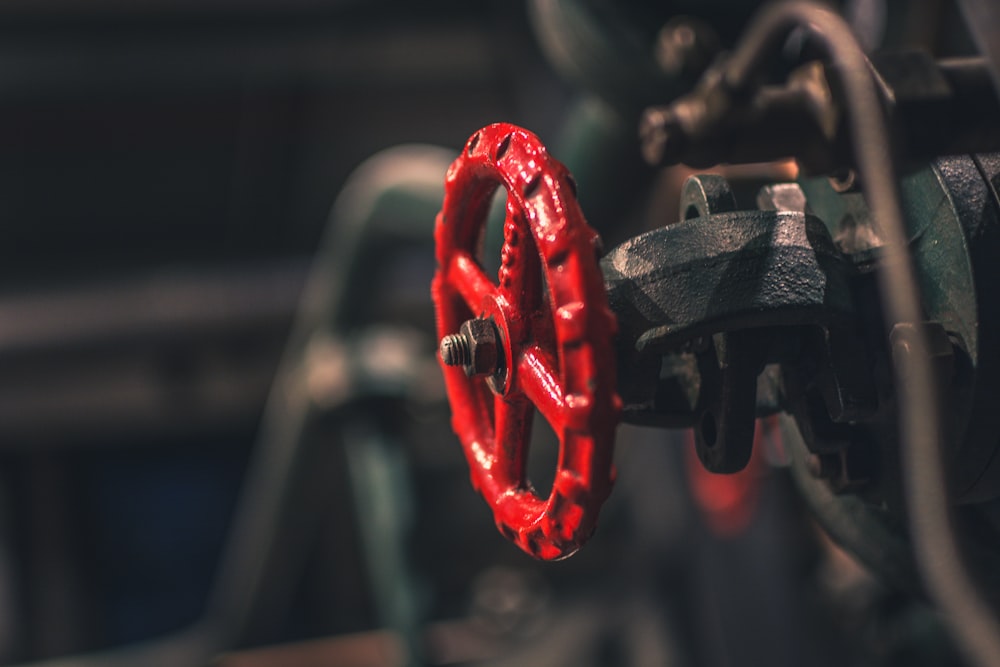

Valve is a very important thing in the modern industry. In the industry, the valve is an important part of the fluid transportation system, which is mainly used in the main equipment, pipelines or systems to control the direction of media flow, control the size of the flow, adjust the pressure of the medium device. Valves have the main function of regulating and controlling the flow rate and direction of the medium, cutting off or opening and closing machinery and equipment, changing unstable liquid or gas into stable fluid, etc. They are usually used to play the role of control, regulation and circulation pressure in various systems. It can control the flow of various types of fluids such as air, water, steam, various corrosive media, slurry, oil, liquid metal and radioactive media.

If you are looking forward to using valves in your business, you may consider brass valves Malaysia as an option. However, in the following article, some information about valves will be presented for those of you who do not know much about them. However, in the following article, some information about valves will be presented to provide some basic knowledge about them for those of you who are still not familiar with them.

Features of Valves

Can control the direction of fluid flow: In fluid systems, valves can control the direction of fluid, pressure, flow, so that the medium (liquid, gas, powder) in the equipment flow or stop. It has the function of inflow, cut-off, throttling, check, diversion or overflow pressure relief, etc. It can be used to control the flow of various types of fluids such as water, steam, oil, gas, slurry, various corrosive media, liquid metals and radioactive fluids.

Small opening and closing force: Due to the small opening and closing force, its structure is smaller than small. The valve has several advantages. First, it has good sealing performance, which ensures safety and also achieves good sealing effect. Most of the valve surface is made of high-temperature alloy, fluorine rubber, carbide or other materials, which have good wear resistance, high temperature resistance, abrasion resistance, corrosion resistance, low temperature and other characteristics, and have good sealing performance under all kinds of working conditions in Malaysia.

Second, strong anti-leakage performance: butterfly valve because the valve flap is sealed together with the valve seat, there is no leakage point on the valve flap, and thus the opening and closing force and anti-leakage ability is strong, which is the reason for the good wear resistance of the valve flap.

Short life span of valve flaps: Because of the special structure of valves, they may fail due to abrasion or wear under certain working conditions. Therefore, their service life is generally a little shorter than that of electric actuators, especially under the working conditions of high temperature, high pressure, corrosive and corrosive media containing. Therefore, to extend the service life of these parts, it is necessary to take reasonable measures in the production process to ensure the intact condition of these parts during operation and to avoid deformation, wear and abrasion of the parts.