In precision industries such as pharmaceuticals, electronics, and research laboratories, maintaining clean and controlled air environments is essential for quality assurance and sensitive processes. A technology called laminar flow malaysia plays a crucial role in achieving this by providing a continuous stream of purified air . In Malaysia, where precision industries thrive, understanding the advantages and importance of laminar flow is essential. This article aims to provide valuable insights into laminar flow in Malaysia, highlighting its usage and benefits in creating clean air environments for precision industries.

The Advantages of Laminar Flow Systems

- Particle Control:

Laminar flow systems excel at controlling airborne particles. These systems employ high-efficiency particulate air (HEPA) filters that capture and remove particles as small as 0.3 micrometers with a high efficiency rate. This particle control capability ensures a clean and sterile environment, minimizing the risk of contamination and ensuring the integrity of sensitive processes and equipment.

- Consistent Airflow:

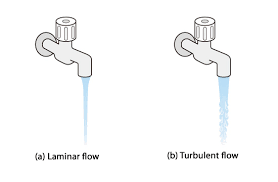

Laminar flow systems provide a consistent and uniform airflow in a controlled direction. The air flows in a parallel, unidirectional manner, maintaining a steady stream of clean air throughout the workspace. This eliminates turbulence and minimizes the potential for cross-contamination, creating a reliable and stable environment for precision industries.

The Importance of Laminar Flow in Malaysia

- Pharmaceutical and Biotechnology Industries:

In the pharmaceutical and biotechnology industries, maintaining strict hygiene and preventing cross-contamination is paramount. Laminar flow systems are extensively used in cleanrooms and production areas to provide a controlled and sterile environment for drug manufacturing, aseptic filling, and research processes. The importance of laminar flow technology cannot be overstated, as it ensures the quality and safety of pharmaceutical products and protects the integrity of sensitive biological materials.

- Electronics and Semiconductor Manufacturing:

Precision industries such as electronics and semiconductor manufacturing require dust-free environments to ensure optimal performance and quality of products. Laminar flow systems are utilized in cleanrooms and production lines to minimize the presence of airborne particles that can damage sensitive electronic components. By creating clean air environments, laminar flow technology plays a crucial role in preventing defects and enhancing product reliability.

Usage of Laminar Flow Systems in Precision Industries

- Cleanrooms and Laboratories:

Cleanrooms and laboratories in Malaysia rely on laminar flow systems to create controlled environments with minimal particulate contamination. These systems are used in various applications, including research laboratories, biotechnology facilities, and precision manufacturing plants, to provide clean and sterile conditions for critical processes.

- Microbiological Safety Cabinets:

Microbiological safety cabinets (BSCs) are essential in biological and pharmaceutical research. Laminar flow technology is integrated into BSCs to ensure a sterile working environment for handling pathogens and hazardous substances. The laminar flow of air within the cabinet creates a protective barrier, preventing contamination and safeguarding personnel.

Conclusion:

Laminar flow technology plays a vital role in Malaysia’s precision industries by creating clean and controlled air environments. The advantages of laminar flow systems include particle control and consistent airflow, ensuring sterile conditions and minimizing contamination risks.

In pharmaceutical, biotechnology, electronics, and semic

onductor industries, laminar flow technology is of utmost importance in maintaining product quality, protecting sensitive processes, and enhancing workplace safety.

By utilizing laminar flow systems, precision industries in Malaysia can optimize their operations, improve product reliability, and uphold the highest standards of quality assurance.